Page 140 - 2025年7月防腐蚀专辑

P. 140

冷 阳等:石墨烯包覆空心玻璃微球改性水性环氧富锌防腐涂料

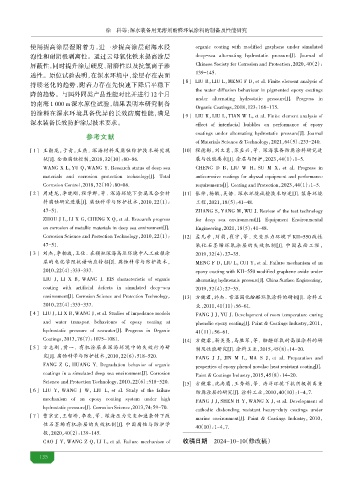

察到有部分凸起,可能是较大粒径的空心玻璃微珠

和锌粉造成的,但 RGO-HGM 含量为 8% 时,其涂层

表面明显出现孔 ,可能是 RGO-HGM 含量较多时,

过多的微球被自身碰撞 压造成 HGM 的破 ,使涂

层的致密性变差。

为了了解负载在 HGM上的石墨烯在富锌涂层中

(a)—0 (b)—2% (c)—4% (d)—6% (e)—8%

的作用,采集了 RGO-HGM 添加量为 4% 的涂层断面

图6 不同RGO-HGM含量的环氧富锌涂料的 28 d耐盐 性

形貌,如图 5(f)、(g)所示,图中显示,涂层中添加的

Fig. 6 28-day salt spray resistance test of epoxy zinc-rich

RGO-HGM 不仅与树脂有较好的黏着性,同时与颗粒 coating with different RGO-HGM addition

状的锌粉有着较好的连接,与“ 独”的锌粉接触完 量为 8% 时,防腐性能反而下降。经过热还原的氧化

成搭接作用,使其能参与阴极保护作用。 石墨烯能够部分恢复导电能力,同时通过负载在HGM

2. 2. 2 涂层耐盐雾性 上,提高锌粉利用率。RGO-HGM 在涂层中可以发挥

不同 RGO-HGM 含量的环氧富锌涂料的耐盐 三方面作用,提高石墨烯在涂层中的分散均匀性,增

性测试结果如图6所示。 强物理屏蔽作用和发挥导电作用提高锌粉利用率。

由图6可知,纯环氧富锌涂层耐盐 时间较短,在 2. 2. 3 涂层电化学性能

第10 d出现涂层脱落的现象,而到第28 d时腐蚀已十 电化学交流阻抗谱测试可以进一步研究

分严重。添加 RGO-HGM 后,随着其含量增多,涂层 RGO-HGM对环氧富锌涂层防腐性能的影响,结果

的防腐效果先增后减,含量为6%时防腐效果最好,含 见图 7。通过对各试样 24 h 和 144 h 时的 Nyquist 图

g g (Ω·cm 2 ) - /×10 8 ] (Ω·cm 2 ) lg[ / (°) 相位角/ g g

×10( ·cm) lg(f/Hz) lg(f/Hz)

8

2

/

(a)—Nyquist图,24 h

(b)—Bode图,24 h (c)—相位角,24 h

g (Ω·cm 2 ) ] (Ω·cm 2 ) (°) 相位角/ g

g

g

- /×10 7 lg[ /

×10( ·cm)

lg(f/Hz)

lg(f/Hz)

7

2

/

(d)—Nyquist图,144 h (e)—Bode图,144 h (f)—相位角,144 h

? ? ? ? ?

图7 不同RGO-HGM含量的环氧富锌涂层在 3. 5%NaCl 介质中 24 h和144 h的电化学交流阻抗谱

Fig. 7 EIS test results of epoxy zinc-rich coating with different RGO-HGM additions soaked in 3. 5%NaCl solution for 24 h and 144 h

137